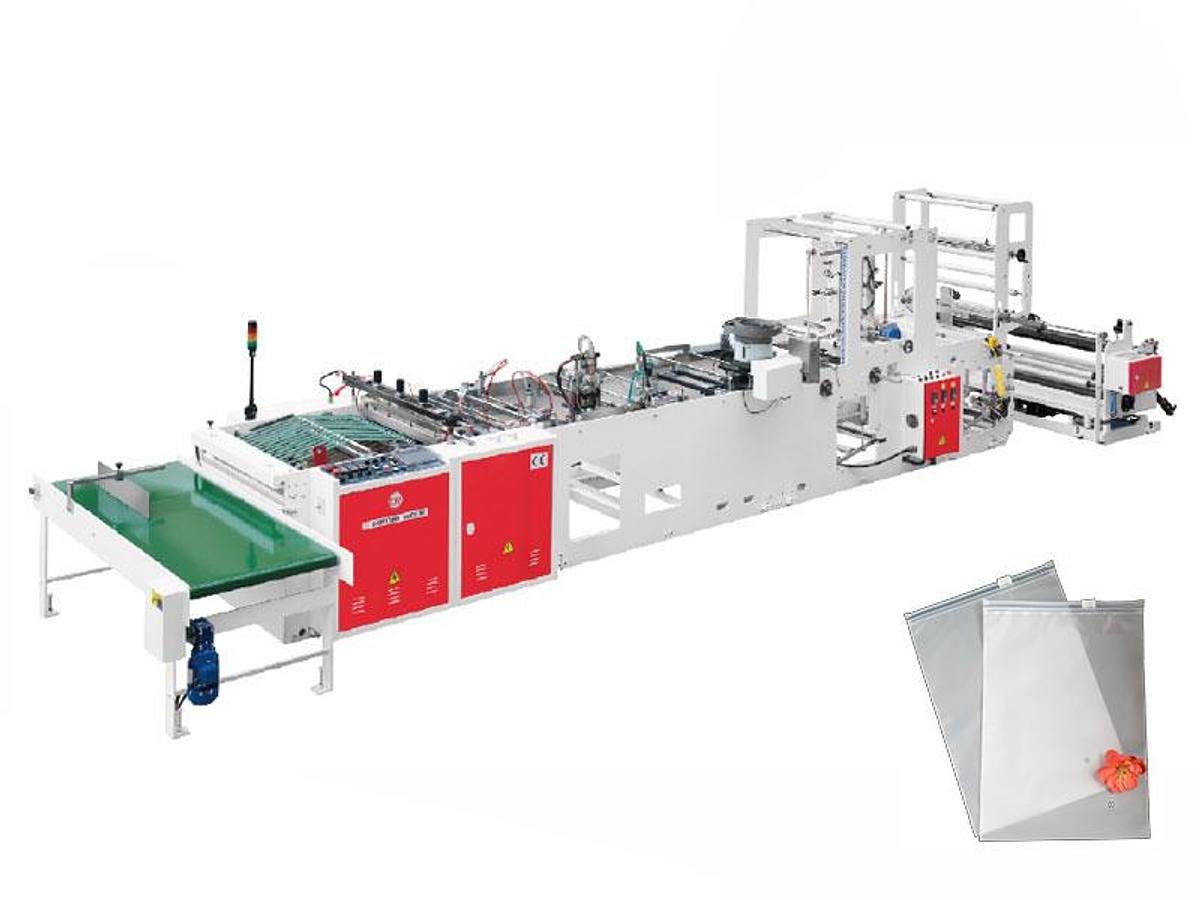

CW-800SBD+ZP Automatic Ziplock Bag Making Machine

CW-800SBD+ZP Automatic Ziplock Bag Making Machine

or

Call +32 53 67 07 89

Description

Automatic Ziplock Bag Making Machine

This is CW-800SBD+ZP automatic ziplock bag making machine to seal plastic zipper reel to Plastic film, in order to form the zipper bags with or without slider head. Special design of PE zipper bag making machine, fully automatic produce,the operation with more simplify design.

Main Features

1. unwinding with air cylinder loading.

2. low friction top fold and bottom gusset device.

3. easy operation zipper heat sealing device.

4. heavy duty side seling knife,easy clean .

5. with multiterm automatic warming,automatic stop device.

6. new design liquid crystal screen, with 5 kinds of language choose.

Optional Equipment

1. handle puncher design.

2. double lines sealing knife and bottom sealing knife.

3. round bottom chicken device.

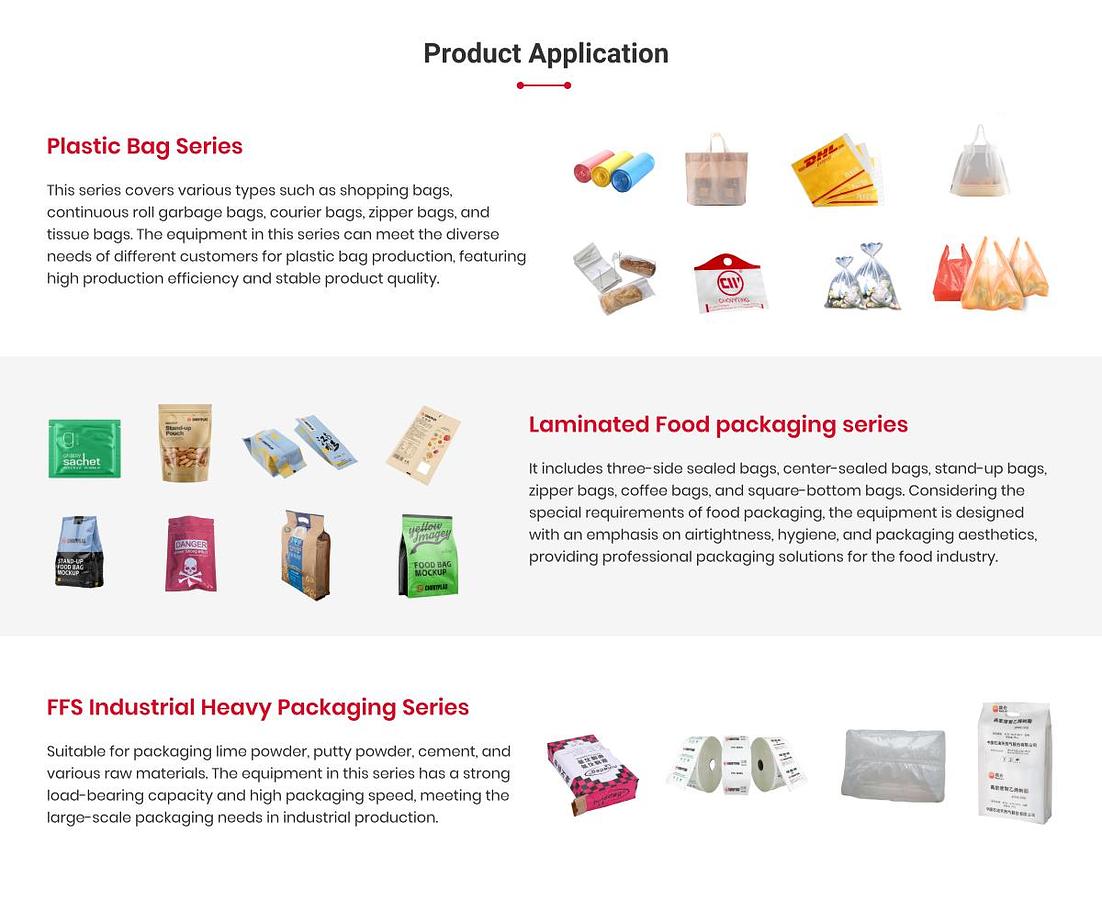

Ziplock bag making machine is an automated roll to bag production line. Its core working principle is to continuously make a bag with a resealable zipper from two rolls of flat plastic film (usually polyethylene PE or polypropylene PP) through a series of processes.

How To Make Small Bags Out Of Ziplock Bag Making Machine

Replace the film roll and zipper, accurately adjust the machine parameters, and replace or adjust the guide rollers, conveyor belts, etc.

Bottom Vs. Side Seal Zipper Bag Making Machine

These are two different machine designs, with the core difference being the forming direction of the bag and the position of the zipper, suitable for different products and needs.

Simple summary selection:

If you need to produce large quantities, universal, and low-cost regular zipper flat pockets, choose a bottom sealed zipper bag machine.

If you focus on high value-added packaging bags that require display, standing, or special structures (such as breathable holes, easy to tear openings), choose a side sealed zipper bag machine.

Related Posts- A Deep Dive: Bottom Seal vs. Side Seal Bags

- Advantages of Using a Side Seal Bag Making Machine

- Applications of Side Seal Bag Making Machines in Different Industries

- Side Seal Bag Making Machine VS Bottom Seal Bag Making Machine

- Structure and Components of a Side Seal Bag Making Machine

- What Is a Side Seal Bag Making Machine and How Does It Work?

Automatic hydraulic loading unwinder 1.the max.diameter of the unwinder is 600mm, the unwinder shaft adopt plug-shaft

2.unwinder with epc device

2.With water cycle cooling system.

3.With concealed style heating tube, temperature steady

Specifications

| Manufacturer | Chovyting |

| Condition | New |

| Subcategories | Side seal bags |

| 3.manual magnetic power tension control | Zipper sealing part Special for sealing zipper with high temperature. |

| Slider head feeding applicator & ultrasonic crusher the ultrasonic unit is for making the zipper seal well. | Heavy duty side sealing knife Sealing and cutting part 1.Side sealing knife principal axis transmissionbelt cylinder lifting and down. |