CW-800FLB OPP Hot Weld Knife Flower Packaging Plastic Bag Making Machine Manufacturer

CW-800FLB OPP Hot Weld Knife Flower Packaging Plastic Bag Making Machine Manufacturer

or

Call +32 53 67 07 89

Description

Brief Introduction

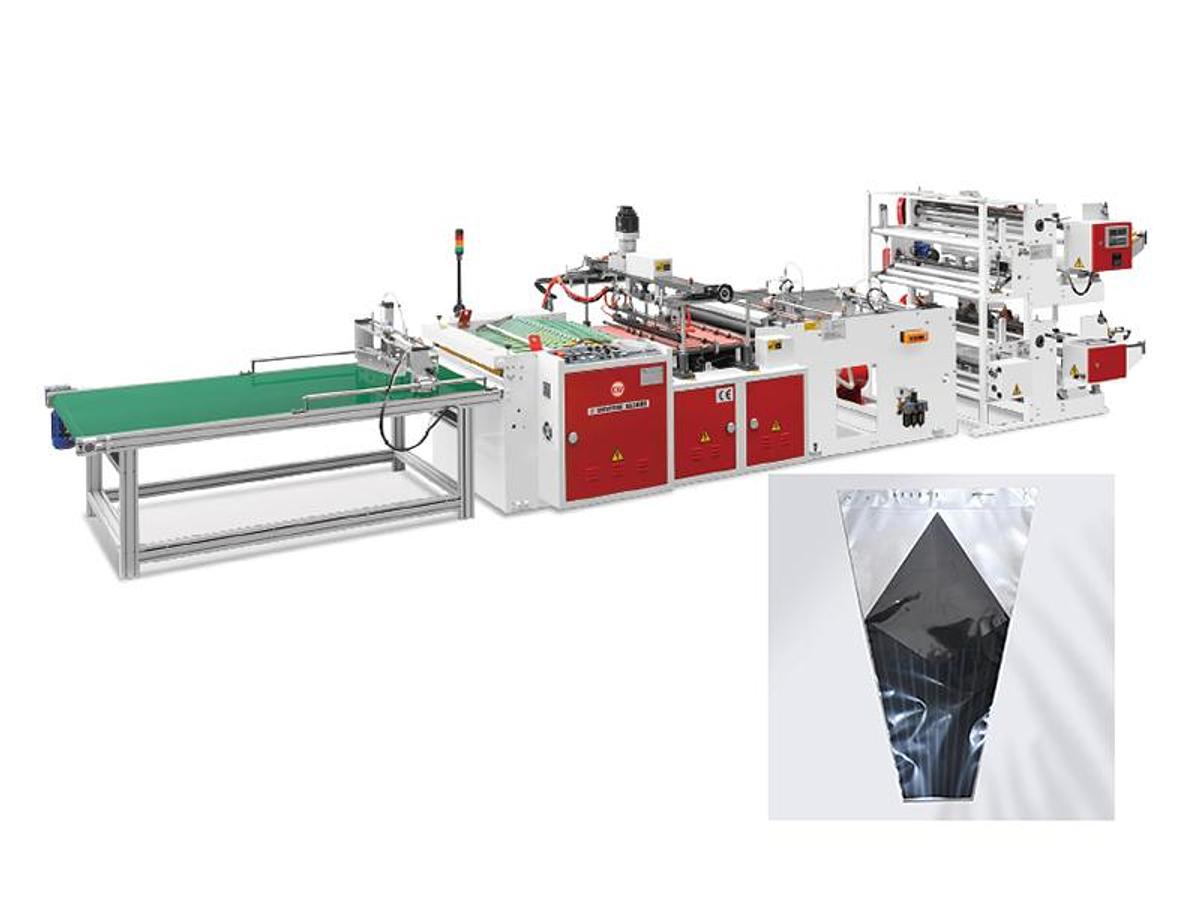

CW-800FLB FOR FLOWER BAG SOLUTIONS

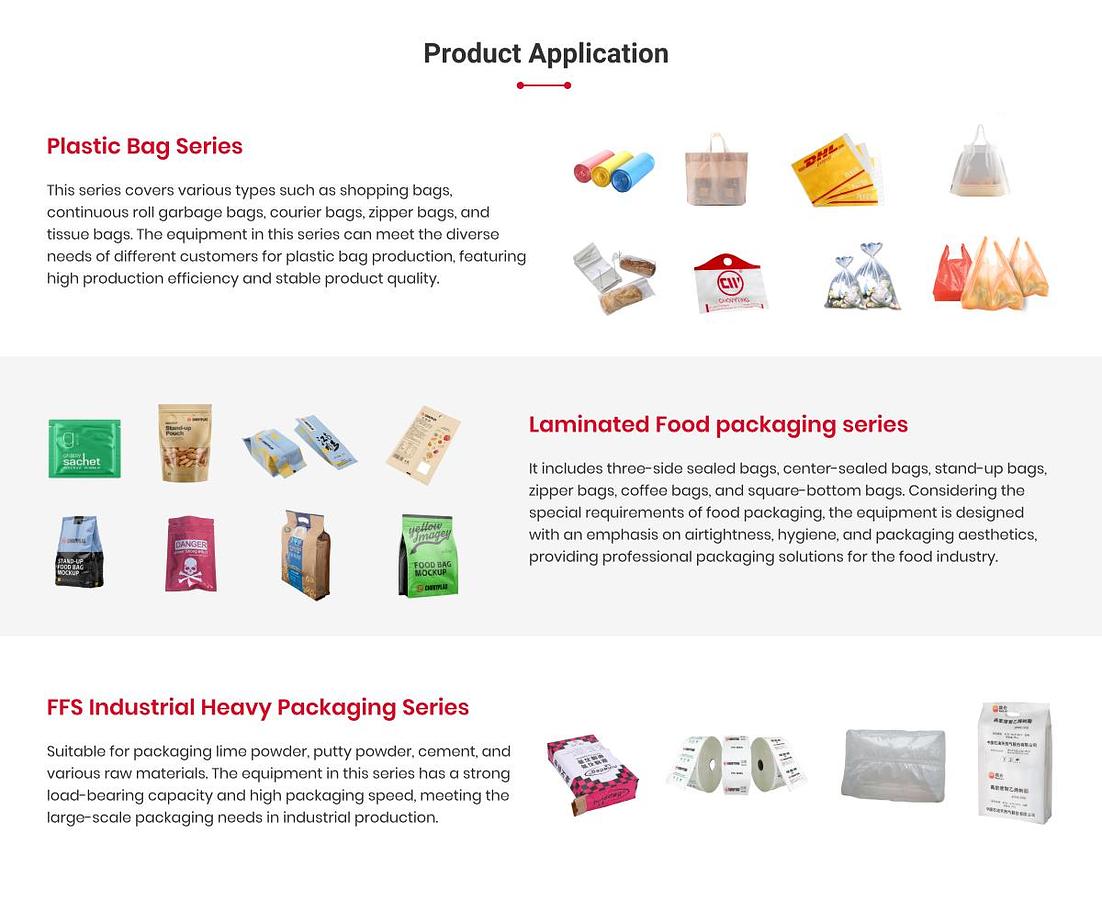

Application

This automatic plastic bag making machine is suitable for making bopp flower bag, fruit bag and other irregular shape bag

Feature

1. Whole machine computer control with touch screen

2. Independent unwinder with mechanical shaft controlled by magnetic powder brake

2. EPC device

3. Material feeding controlled by step motor or servo motor

4. Heat sealing heat cutting

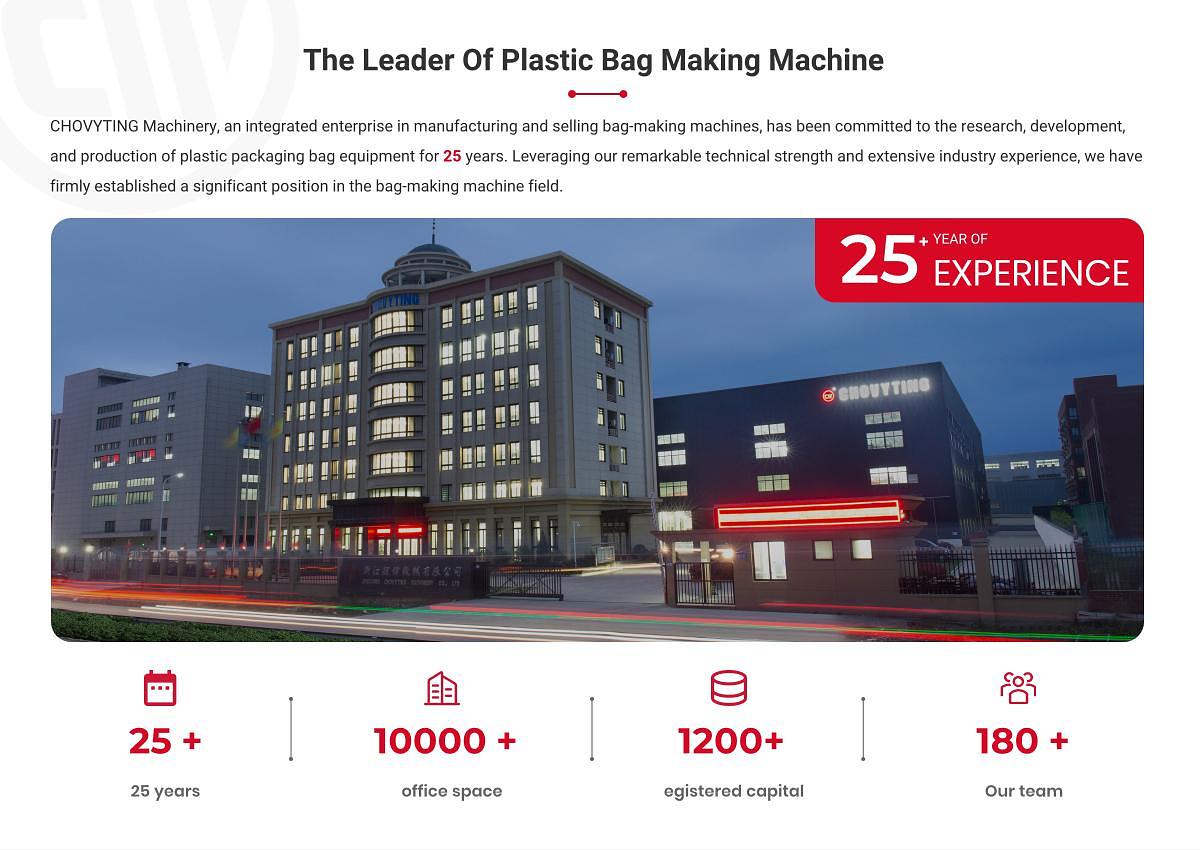

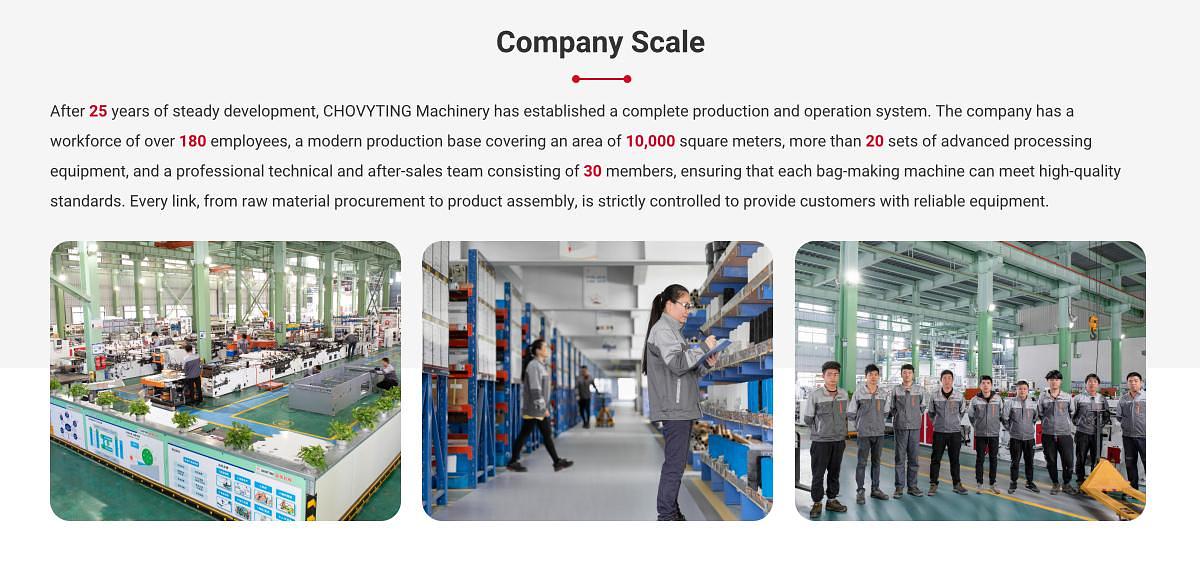

Making plastic bags primarily uses plastic bag-making machines, which typically include blown film machines, printing machines, bag cutters, and sealing machines. Chovyting Machinery offers fully automated plastic bag making machines that efficiently complete the entire process from blown film from plastic granules, printing, cutting, and sealing, suitable for various plastic bag production needs.

How much does it cost to make plastic bags?

The total cost of manufacturing plastic bags depends on factors such as raw materials, electricity, labor, and machine depreciation. Using high-quality plastic bag-making machines, such as those from Chovyting Machinery, although the initial investment is higher, can reduce production costs in the long run due to their high efficiency and low failure rate. A rough estimate is that the cost of one kilogram of plastic bags for small-scale production is about $1-2, while large-scale production can reduce it to below $0.50.

How are plastic bags made step by step?

The tubular film is printed with patterns using a printing machine; then, a bag cutter cuts the film into specific shapes; finally, a sealing machine seals the edges to form the finished product. Throughout the process, Chovyting Machinery’s plastic bag-making machines integrate these steps to achieve automated production line production, ensuring efficient and consistent quality output.

Related Posts- 9 Different Types Of Plastic Bag Making Machine

- Detailed Overview of Various Types of Plastic Bag Making Machines

- Plastic Shopping Bag Making Machines Guide and Reliable Supplier Choose

- Solution of plastic bag making machine

- The prospect of plastic bag making machine

- Top10 Plastic Bag Making Machine Supplier 2025

2. When the bag reach to a certainty quantity, collect table will move automatically, and continuo producing.

3. Collect table is driven by Micro-motor reducing servo

Unwind part 1. design of double layer unwinding. 2. the roll tension is controlled by magnetic powder brake 3. the upper and lower

Specifications

| Manufacturer | Chovyting |

| Condition | New |

| Subcategories | Side seal bags |

| Line speed | 30 m/min |

| Max.height of the bag | 700mm |

| Max.width of the bag | 600mm |

| Mechanical speed | 50-100CPM/MIN |

| Rotating side sealing knife and conveyor belt part 1. rotary side seal blade design, servo motor drive, the angle of swing set by the touch screen, simple operation, easy to clean. 2. equipped with side seal flower knife, can be exchanged with flat knife | COLLECTION STATION PART 1. Collect table adopt automatic collecting bag feeding (inter-mission model and continuum model) |

| The machine size | 6500x1750x1870 mm |

| Total power | 10.5kw |

| Unwinding is attached with automatic epc correction device. 4. with no material, cut off automatic shutdown device. | PRINTING TRACKING AND BAG FEEDING PART 1. The color standard electric eye adopts Germany (LEUZE) photoelectric sensor, zero fault, accurate sealing and cutting size. 2. The bag feeding adopts Japanese Yaskawa servo motor drive, high-speed transportation, accurate positioning. |