CW-800SP Volledig automatische patch-handvat zakkenmaker

CW-800SP Volledig automatische patch-handvat zakkenmaker

of

Bel +32 53 67 07 89

Beschrijving

Fully Automatic Patch Handle Bag Making Machine

The CW-800SP fully automatic patch handle bag making machine integrates mechanical, optoelectronic, and pneumatic technologies to efficiently achieve the integrated production of patch handles and die-cutting handle shopping bags. One machine dual use, greatly improving production flexibility and efficiency, is your intelligent choice for cost reduction and efficiency improvement. Welcome to contact us for exclusive solutions!

Brief introduction:

This machine has 2 functions ( patch handle bag,die cut handle bag). It is coupled with machinery, light, electronic and pneumatic.

Including:

1. side sealing knife

2. Folding unit

3.Automatic collect table

OPtional equipment:

1.Single sheet film fold unit(hydraulic auto loading device)

2.Double sealing knife device

3.Bottom sealing knife device

Related Posts

- CW-500ZD Fully Automatic Bottom Seal Soft Loop Handle Bag Making Machine

- CW-800CSD Super High Speed Automatic Soft Loop Handle Bag Making Machine

- CW-800LP Fully Automatic Soft Loop Handle Bag Making Machine

- CW-800NJT Fully Automatic High Speed Inside Glue Patch Handle Bag Making Machine

- CW-800SDP Fully Automatic High Speed Handle Bag Making Machine

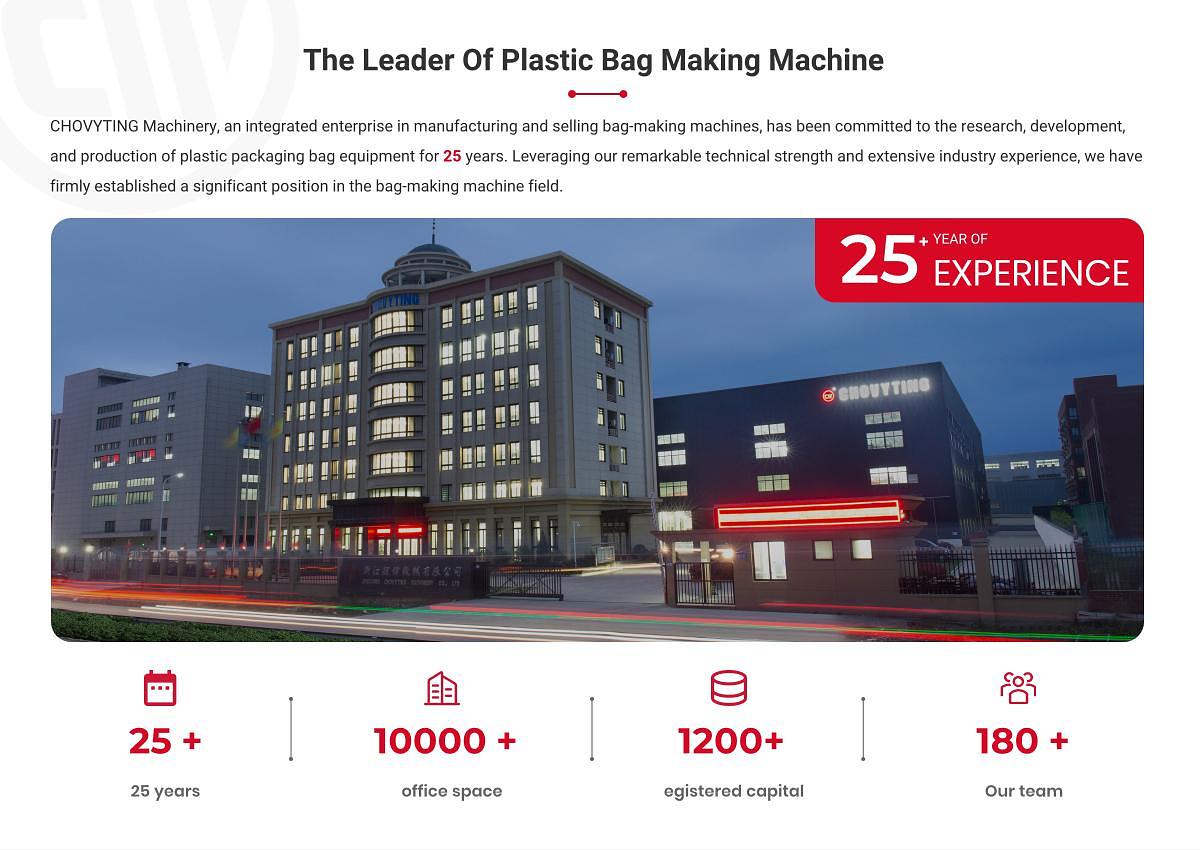

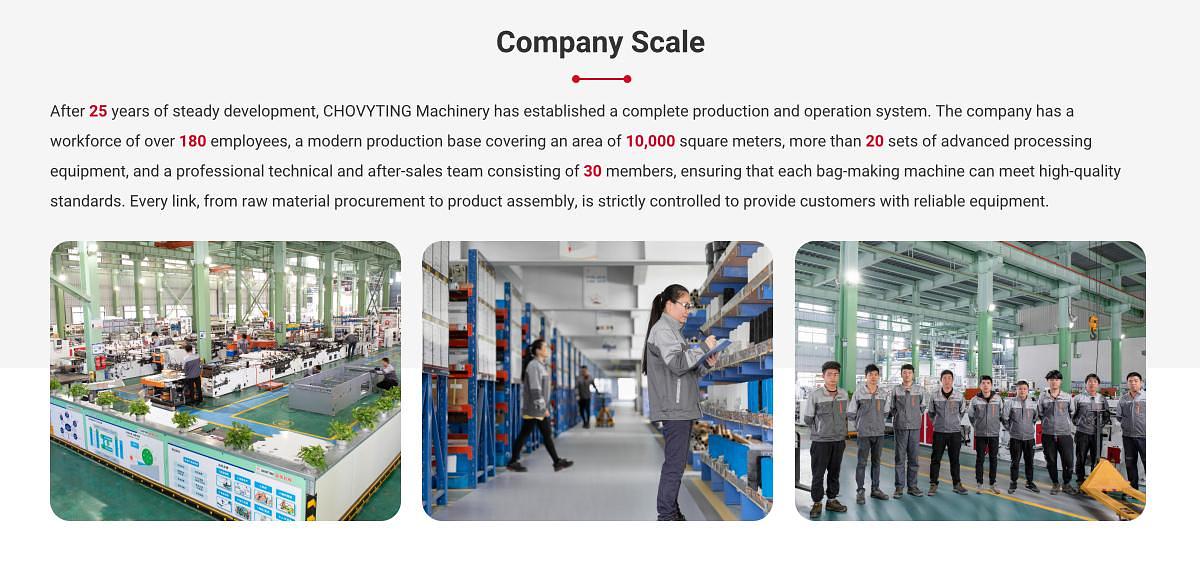

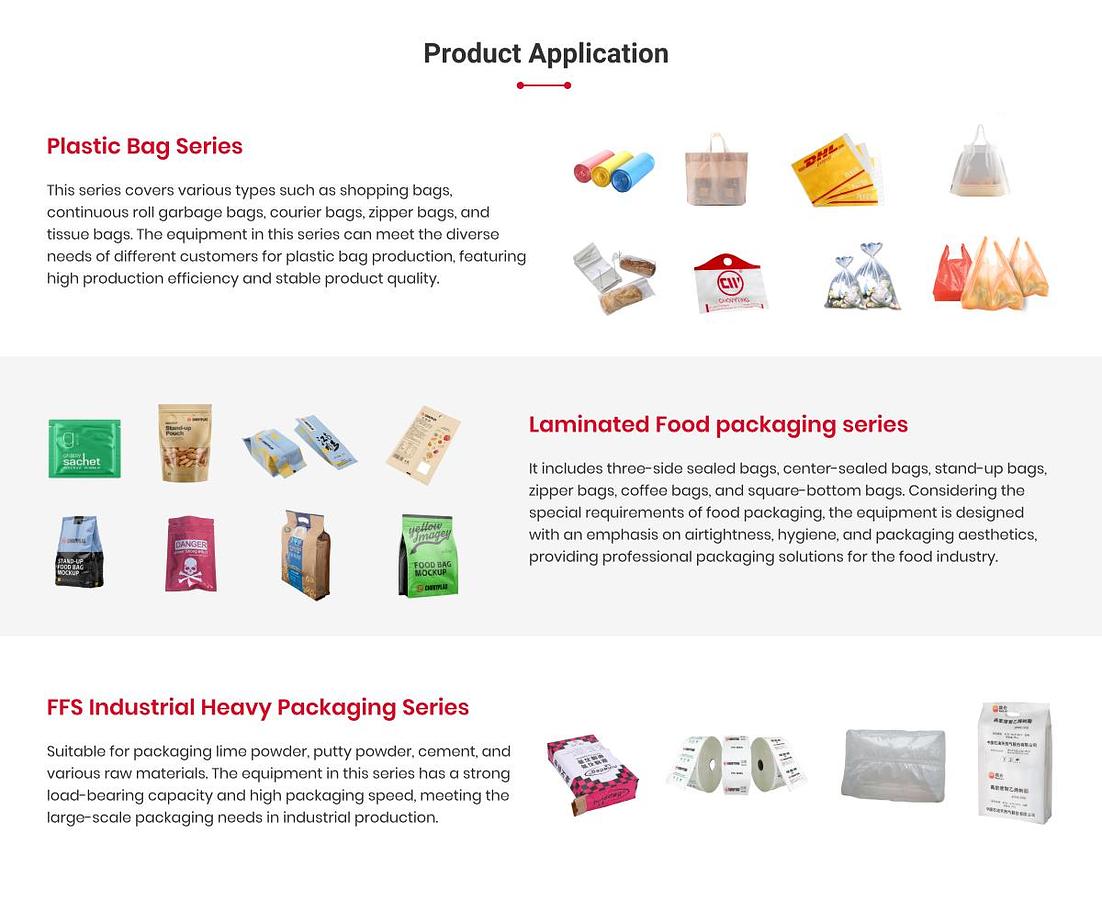

CHOVYTING Machinery is a manufacturer specialized in the design and production of plastic bag machinery.Due to our strong R&D team, we accept customization of special machines, welcome to consult +86 13958813143(WhatsApp)

Related Posts - A Deep Dive: Bottom Seal vs. Side Seal Bags

- Advantages of Using a Side Seal Bag Making Machine

- Structure and Components of a Side Seal Bag Making Machine

- What Is a Side Seal Bag Making Machine and How Does It Work?

- CW-500ZD Automatic Bottom Seal Soft Loop Bag Making Machine

- Side Seal Bag Making Machine VS Bottom Seal Bag Making Machine

- Applications of Side Seal Bag Making Machines in Different Industries

- Semi-Automatic Vs Fully Automatic Bag Making Machines:7 Key Differences

Common unwinding 1. unwinding adopt common loading , max diameter of raw rolling materialisφ600mm

2. adopt magnetic powder tension control. manual adjust the tension.

2. Inside heating wire sealing, which is suitable for full colors of bag.

3. Adopt import heat wire, steady warming, hard sealing

3.1x

1.87m

Side sealing parts 1.side sealing knife with water cycle cooling system.

2.side sealing knife adopt best of breed material, high temperature heating ametabolic.

2.When the bag reach to a certainty quantity, collect table will move automatically, and continuo producing.

3.Collect table is driven by Micro-motor reducing servo

Specificaties

| Fabrikant | Chovyting |

| Model | CW-800SP |

| Conditie | Nieuw |

| Subcategorieën | Draagtassen |

| Onderste gusset | 20-70mm |

| 3. afrolas is zwaar-kettingplug as | Top-vouwende continu afdichtingssysteem 1. Top-vouwende continu afdichting, de breedte van de zak is niet beperkt |

| Die gesneden handvat zak | 80pcs/min |

| Lengte van de zakmaker | 250-750mm |

| Machine dimension(lxwxh] | 8x |

| Machine gewicht | 3200kg |

| Patch handvat tas | gestanst handvat zak |

| 3. zijkant afdichtmes met verhulde stijl verwarmingsbuis, temperatuur stabiel | Transporteer verzamelapparaat 1. Verzameltafel gebruikt automatische zakkenvoer (onderbrekingsmodel en continu model) |

| Topvouwrand | 50-75 mm |

| Totale kracht | 10KW |

| Breedte van zakvormende | 250-800mm |